Solar thermal

Solar thermal designates the transformation of light radiation into heat. This is the same energy that allowed the development of life on Earth, through the atmospheric warming and photosynthesis. Originally used to light the sacred fire, that energy could be one solution to the energy challenges of our century.

Contents

[hide]History

The history of solar thermal energy begins in Greece in the 8th century BC. JC. Indeed, during the opening ceremony of the first Olympic Games of 776 BC., the Olympic flame was lit by the sun with the skaphia, the ancestor of the parabolic mirror[1].

The invention of the burning mirror is reused five centuries later by Archimedes during the siege of Syracuse (Sicily). While the Greek colony was attacked by the Roman fleet, legend says that Archimedes had developed giant polished bronze mirrors to reflect and concentrate the sun's rays to burn the sails of Roman ships.

On the other side of the Atlantic Ocean, Inti the sun god of Incas sends Manco Capac, the legendary first emperor of the Incas. So, the worship of the sun became very important. From the fifteenth century, it became one of the most popular rituals: the Inti Raymi (the resurrection of the sun). It takes place in the Inca capital Cuzco during the winter solstice, June 24, and for 9 days during which the Incas were suitable for dancing but also sacrifices. On this occasion, a fire was lit by the High Priest with a gold bracelet: the chipana[2].

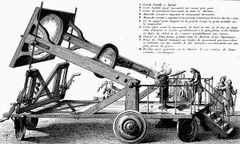

In Europe, we must wait the 16th century and the coming of Leonardo da Vinci to give an impetus to solar technologies. In 1515, Leonardo da Vinci invented a new solar concentrator: a sytem of CLFR type (Compact Linear Fresnel Reflector). However, this system seems to have existed only on paper.

In 1615, Solomon Gaus built a solar pump. The driving force was provided by the air heated from solar radiation.

In the 18th century, the burning mirror of antiquity and of the Inca Empire resurfaced in France. Georges-Louis Leclerc, Comte de Buffon built in 1747 a mirror composed of 168 flat glasses of six inches wide and eight high. So he melts different metals such as tin, lead and silver[3].

Experiences around solar accelerate. In 1774,Antoine Laurent Lavoisier, chemist, philosopher and economist, invents a solar cooker composed of converging lenses in order to melt metals.

Still in the 18th century,Horace-Benedict de Saussure develops in 1774 a measurement instrument enabling him to study the heating effects of the sun, the helio thermometer. It looks like "hot" boxes with insulated walls and one or more windows. Horace-Benedict obtained with this device a temperature of 88°C. This invention is both the ancestor of Solar oven and Flat plate collector[4].

In 1874, the first solar distiller was created in Salinas, on top of Atacama plateau in Chile, which produces 23 tons of fresh water on a sunny day. Some decades later, the English physicist Charles Vernon Boys invented and implemented the first cylindrical parabolic collector in 1912. He created the first solar power plant in Meadi, Egypt, used for pumping irrigation water.

We have to wait the end of World War II to find new developments in the field of solar thermal. The French Félix Trombe has the idea of using a DCA projector abandoned by the Germans in Mont-Louis (Pyrénées-Orientales, France). In 1949, he transformed it into Solar oven with a power of 50kW.

In 1963, Italian Giovanni Francia and the French Marcel Perrot install the first CLFR system (Compact Linear Fresnel Reflector) in Marseille, around 450ans after its invention by Leonardo da Vinci.

Meanwhile, the furnace of Mont-Louis knows a good level of performance. Thus the French government built a solar oven almost industrial in Odeillo. Commissioned in 1970, the solar oven of Odeillo has a capacity of 1MW.

In 1983, EDF and CNRS build Themis, the first French electrosolar central tower with a power of 2500 kW. However, the political of all nuclear will surpass it, and it closed three years later.

Today, as a result of environmental awareness and rising fossil energy, policies for renewable energy have increased over the 5 continents.

Principle

The different technologies

The components of a thermal collector

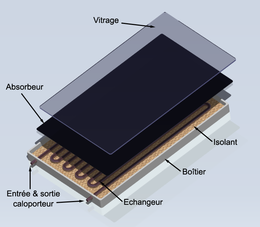

A thermal collector is the element which absorbs the solar radiation to convert it into heat. This heat is then transmitted to a heat transfer fluid. A collector is composed of an absorber, a heat transfer fluid, an insulation, and sometimes a glazed reflectors.

the absorbers

The absorber is one of the most important elements of a thermal collector, it converts solar radiation into heat.

The absorber is characterized by two parameters:

- the solar absorption factor α* (or absorptivity): the ratio of light radiation absorbed by the light radiation incident;

- the infrared emission factor ε (or emissivity): the ratio of the energy radiated in the infrared when the absorber is hot by the one that a black body radiate at the same temperature.

In solar heating applications, we try to obtain the best ratio solar absorption factor / infrared emission factor. This ratio is called selectivity.

The material constituting the absorber is generally made of copper or aluminium but sometimes also made of plastics material.

To obtain better performance, some systems are therefore made of a particular coating.

Here are the properties of some materials used as absorbers:[5]

| Materials | absorptivity α* |

emissivity ε |

selectivity α* / ε |

Max. temperature |

|---|---|---|---|---|

| Black nickel | 0,88 - 0,98 | 0,03 - 0,25 | 3,7 - 32 | 300°C |

| Graphitic films | 0,876 - 0,92 | 0,025 - 0,061 | 14,4 - 36,8 | 250°C |

| Black copper | 0,97 - 0,98 | 0,02 | 48,5 - 49 | 250°C |

| Black chrome | 0,95 - 0,97 | 0,09 - 0,30 | 3,2 - 10,8 | 350 - 425°C |

the heat transfer fluids

The heat transfer fluid serves to evacuate the heat absorbed by the absorber and to transmit it where it should be consumed. A good heat transfer fluid must have the following conditions:

- Be chemically stable when it reaches a high temperature, especially during the stagnation of the thermal collector;

- Have antifreeze properties in correlation with local weather conditions;

- Have anticorrosive properties depending on the nature of the materials present in the thermal collector circuit;

- Have a specific heat capacity and a high thermal conductivity in order to effectively transport heat;

- Be non-toxic and have a low impact on the environment;

- Have a low viscosity to facilitate the work of the circulation pump;

- Be easily available and cheap

A good compromise with respect to these criteria is a mixture of water and glycol (used in the coolant auto), although it is not uncommon to find systems running on pure water or simply air depending on usage.

the glazing

The glazing protects the inside of the thermal collector against environmental effects and improve system performance by greenhouse.

If an efficient glazing is desired, it must have the following properties:

- Reflect the light radiation to a minimum regardless of inclination;

- Absorb light radiation to a minimum;

- Have good thermal insulation by keeping the maximum infrared radiation;

- Resist in time the effects of the environment (rain, hail, sunshine, ...) and large temperature variations.

The main galzings used as thermal collectors are glass-based non-ferruginous or acrylic glass, often provided with an antireflection coating.

thermal insulation

Thermal insulation limits heat loss, its characteristic is the conductivity factor; the lower it is the better is the insulation. The main materials used for the thermal collectors are rock and glass wool, polyurethane foam or melamine resin. We sometimes find more natural insulators.

Some insulation used for thermal collectors:

| Materials | Thermal Conductivity |

|---|---|

| Rock wool | 0,032 - 0,040 W/m.K |

| Glass wool | 0,030 - 0,040 W/m.K |

| Polyurethane foam (insulation) | 0,022 - 0,030 W/m.K |

In the case of glass thermal collectors, it is also interesting to replace the insulation between the glass and the absorber.. by air! Indeed, the air has a high insulating power, and it is used in double glazing. Always with the objective of better yields, some manufacturers use other gases such as argon or xenon, and whenever possible, it is even preferable to use.. vacuum!

Here insulation gas coefficients used as insulation:

| Gaz | Thermal conductivity at 283 K, 1 bar. |

|---|---|

| Air | 0,0253 W/m.K |

| Argon | 0,01684 W/m.K |

| Xenon | 0,00540 W/m.K |

the reflectors

Reflector has the function to direct the radiation, which couldn't reach the absorber otherwise. It is generally used to reach very high temperatures or used for some systems such as vacuum tubes collectors.

Reflectors, to be effective, must have the following properties:

- Reflect maximum light radiation;

- At least absorb light radiation;

- Be perfectly smooth to avoid accumulation of dirt;

- Resist in time the effects of the environment (rain, hail, sunshine, ...);

- In some applications, to resist temperature variations.

The reflector is often used in order to focus the light rays, so it has a particular shape which can be:

- Parabolic trough: This geometry allows a linear focus, it is used in the case of collectors or evacuated tube solar thermal plants Luz kind.

- Sphere: the spherical reflector focuses sunlight onto a mobile linear focus driven by a radius of the sphere directed towards the Sun.

- Parabolic: This is the type of geometry used most. It allows to focus the light rays to a point to obtain high temperatures. It is often used in the case of solar cookers, or coupled to a Stirling engine.

- Flat: the flat reflector is generally movable to follow the Sun, this is called heliostat plane. This system is used in the case of thermal or solar power tower coupled to a parabolic mirror, as in the case of solar ovens Odeillo category.

The flat plate collectors

The flat plate collector remains the simplest and most widely used technology. There are two types of flat plate collectors: with glazed and unglazed.

- The glazed flat plate collector consists of an insulated box covered by glazing. Inside, we find the absorber in which circulates the coolant. The glass blocks the infrared radiation and isolates the air blade over the absorber to keep the heat.

- The unglazed flat plate collector is less common, it is only composed of an absorber in which circulates the coolant. Highly dependent on the outside temperature, it is generally used in summer to heat the swimming pool water.

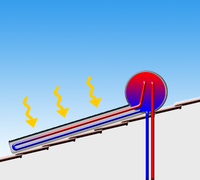

The vacuum tube collectors

The vacuum tube collector also works well in summer and winter. It comprises a series of transparent vacuum tubing that isolates the heat absorber. This type of sensor allows to reach higher temperatures and this faster.

Advantages of vacuum tube:

- Higher operating temperature;

- Reduced heat loss.

Disadvantages of vacuum tubes:

- thermal constraints on materials important;

- Higher costs.

There are different types of vacuum tubes collectors:

- Direct flow: in this type of sensor, the coolant circulates inside the absorber, allowing high efficiency.

- Heat pipe: in the vacuum tube heat pipe, absorber contains a vaporized liquid under partial vacuum. This heated steam is condensed in a condenser and returned in liquid form in the absorber. The condenser, it takes care of transferring heat to the coolant. This system requires a minimum inclination of the absorber tube.

- Of "Sydney" / CPC type tube "Sydney" is characterized by a glass tube double-walled to prevent loss of vacuum. The absorbing surface is located on the inner glass tube. The rounding of the tube requires the use of a reflector for use the whole surface of the absorber, from which its name tube CPC (compound parabolic concentrator).

Applications

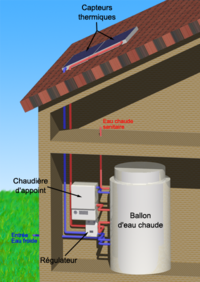

Domestic water heating

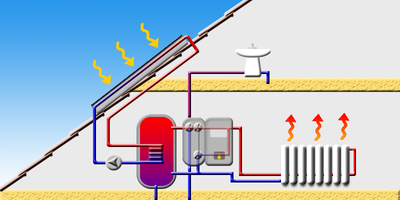

| The domestic water heating is one of the most accessible solar technologies to individuals. The principle is simple: thermal sensors convert light radiation into heat. The coolant flows through the thermal sensors and carries heat to the sanitary water stored in a flask.

Of course, many systems can heat water, each with its advantages and disadvantages. |

|||

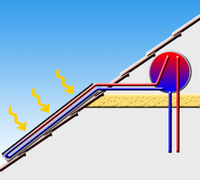

| The monobloc water heater is the simplest system. The temperature sensor and the balloon form a single assembly.

The sanitary water flows directly into the thermal sensors; once heated, the water becomes less dense and rises in the balloon located slightly above the sensor. |

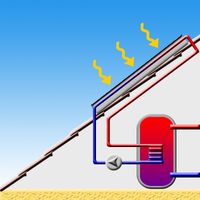

The thermosyphon water heater uses the same principle as the monobloc water heater except that the ball is separated from the thermal sensors. It is then possible to install inside the balloon so that it remains higher than the temperature sensors. | ||

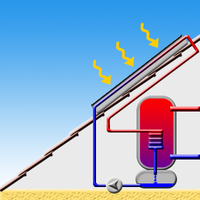

| The water heater with forced circulation uses a coolant that does not fear frost. The fluid is heated within the thermal collectors and carries heat into the flask through a heat exchanger, thereby preventing the mixture with sanitary water.

Once cooled, the fluid returns to the heat sensors with the help of a pump. |

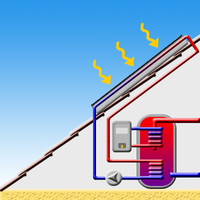

The self-drain water heater has the ability to empty when thermal collectors are subject to the risk of freezing. The flask is always situated lower than thermal collectors: when the sun does not heat the water flow stops and the circuit automatically drain. When the sun reappears, traffic starts again. | ||

| The water heater coupled to an auxiliary boiler is used for reasons of convenience and that whatever the type of solar water heaters. Indeed, it would be a shame to take cold showers in winter.

As there are several types of solar water heater, there are several ways to pair with a backup boiler. |

|||

Pool water heating

The pool water heating is in summer period, during which the risk of frost is negligible. Thermal collectors used are unglazed which require less maintenance, they are performing during this period, and especially they are less expensive. The pool water is pumped into the absorber where it is heated, and then returned to the pool. The system can also be coupled with additional heat, thus providing more comfort.

Advantages:

- Less expensive than glazed collectors;

- Few maintenance.

Disadvantages:

- Large surface collectors;

- Requires chemical treatment of water (pH control, disinfection with chlorine ...).

Space heating

The space heating from solar collectors is not yet well developed although evolving standards of building insulation can make this technology more attractive. The main obstacle is that we mainly need for heating in winter, during which the sun is reduced. There are three ways to heat a room by solar thermal energy: through conventional radiators, ventilation by hot air or underfloor heating.

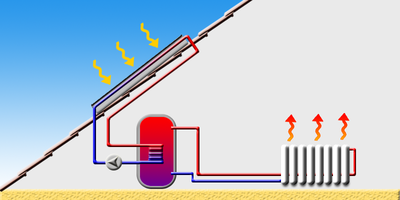

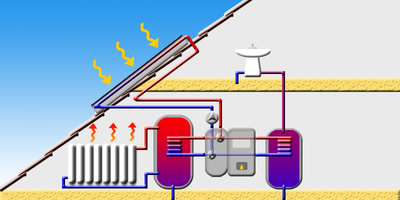

| The conventional heating radiators works very similarly to a domestic water heating.

Thermal collectors transform the light radiation to heat, the heat transfer fluid flows in thermal collectors and carries heat to the heating water stored in a flask. Then hot water circulates inside conventional radiators. |

|

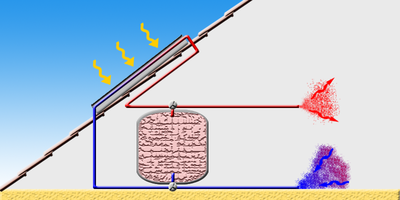

| The heating ventilation by air directly uses air instead of passing a liquid coolant.

A ventilation system draws in outside air through the perforated thermal collectors. The hot air is then stored within a large mass of solid material as the rollers, before being returned into the room. |

|

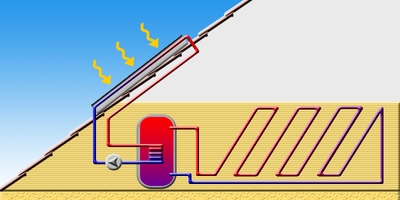

| The underfloor heating functions in the same way as a conventional heating radiators to a difference in integrated floor circuit replaces radiators. This system has the main advantage of operating at a lower temperature. |

Air conditioning

Solar air conditioning is perfectly correlated with the usable solar energy. It is in the sunniest countries that we need to cool. Thermal energy is used as the base for the energy production of cold using conventional systems. There are two types of refrigeration systems, the open systems (absorption and adsorption refrigerator) and closed systems.

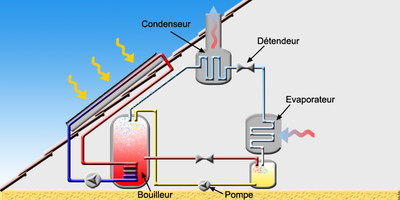

| The absorption refrigerator, as the name suggests uses the absorbent properties of certain fluids. In general the pairs of refrigerant fluid / absorbent is used : Ammonia / water and water / lithium bromide.

The system is composed of the following elements:

|

|

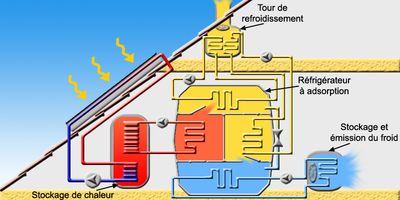

The adsorption refrigerator uses silica gel, an ecologically neutral desiccant which has the property of having a cooling capacity of absorbing water. The system is composed of the following elements:

|

|

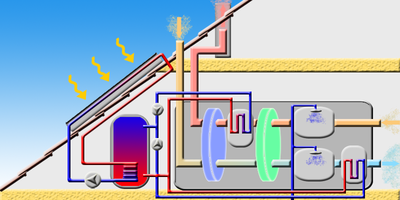

| The sorption Air Conditioning is based on the principle of evaporative cooling with dehydration upstream to improve the cooling power. |

Combined domestic hot water and heating systems

The combined hot water and heating systems have the advantage of using the same types of thermal collectors. A heat transfer fluid is heated in these collectors and then transmits the heat to the storage system. The big difference between the water used for hot water and one for the heating is that they do not have the same temperature. There are two solutions to this problem: the dual storage system and the combined storage system.

| Types of combined systems | Diagrams |

|---|---|

| The dual storage system uses as its name indicates two water heaters; one for hot water and one for heating. The fluid heated by the sensors is regulated to heat domestic water or heating as necessary; and heating is connected to two water heaters to achieve the desired temperature. | |

| The combined storage system has the feature of using only one heater. Solar hot water at the outlet of the water heater is mixed with cold water for sanitary use. Regarding heating, the system is more complex: when the return temperature of the heating is actually lower than the heater while it passes through the heater and by an auxiliary boiler before returning to the heating system. When the return water heater is warm enough, it passes directly through the auxiliary boiler before returning to the heating system to avoid unnecessary heating the water heater. |

The electricity generation

Solar thermal power plants use the sun's light rays to transform into thermal energy and then into electricity using a turbine.

This transmission follows the principle of Carnot and therefore requires maximum temperature rise in order to have the best possible performance.

There are five main types of solar thermal power plants: the parabolic troughs power plants, solar power towers, parabolic reflector power plants, solar updraft towers, Fresnel mirror power plants.

| The parabolic troughs power plants as its name indicates using parabolic troughs to concentrate the light radiation to a tube in which a fluid is heated strongly. This fluid will allow to produce the high pressure steam to power a turbine which generate electricity.

Example: Nevada Solar One[6]

|

|

| The solar power towers are composed of a large number of heliostats directing light radiation to a central receiver located at the top of the tower. The energy absorbed by the receiver heats up a fluid into the high pressure steam, and powering a turbine that generates electricity.

Example: Thémis[7]

|

|

| The parabolic reflector power plants consist of a mobile parabolic reflector that concentrates light radiation to a receiver located at the focus of the dish. The absorbed energy is recovered by a Stirling engine to generate electricity.

Example: Dish-Stirling system of Odeillo[8]

|

|

| The solar updraft towers consist of a base acting as heat air through the greenhouse effect and a chimney in which heated air drives a turbine, producing the electricity. The base is formed of a transparent cover a few meters from the ground. Air seeps below the cover and is heated by greenhouse effect. The temperature difference between the base and the top of chimney creates a suction of the hot air upwards. Like the wind, the rising air rotates a turbine located inside the chimney. Another variant remained in draft form, aims to exchange the chimney with a natural building: the folds of the mountains.

Example: Manzanares[9]

|

|

|

The mirror Fresnel power plants, also known as Compact Linear Fresnel Reflector power plants (CLFR), operate in the same manner that a reflector parabolic trough power plant unlike reflectors are flat and in greater numbers. Each reflector is plane and orientable independently along an axis in order to direct light radiation towards the tube in which circulates the heat transfer fluid. Example: Kimberlina[10]

|

Cooking

The solar oven

The solar oven allows you to cook food by greenhouse. It is formed of a box whose inside is lined with reflectors and a transparent cover on the top. The radiation penetrates inside the box, and is reflected on the surface of a container which absorbs the rays. The transparent cover serves to isolate the oven from the outside and to trap infrared radiation in order to keep the maximum heat.

The solar oven thus has a great advantage: only use the sun as fuel. NGOs disseminate recent years these ovens in sunny countries subject to high deforestation as Madagascar and Bolivia.

The main difficulty of the generalization remains of cultural order. As in Africa, it is difficult to ask a European to replace its barbecue by a solar oven. Despite this, many enthusiasts of solar cooking have been seduced by this concept and have developed different types of solar cookers:

- the solar oven Ulog

- the Sunoven

- the Sun cook

The solar cooker

The solar cooker allows you to cook food by concentrating the light radiation. It usually consists of a parabolic reflector concentrating the light radiation to a container whose surface absorbs radiation.

In general, the solar cooker provides a higher temperature and that than faster solar oven. However, it is more sensitive to the lack of Sun and frequently must be redirected.

As well as solar ovens, the cooker have many fans who have developed under several forms:

- the parabolic solar cooker SK 14

- the Butterfly solar cooker

- the Scheffler solar cooker

- the HotPot

Research

The international research in solar thermal is performed by the national research centers, but also by some private companies. All these national research centers are grouped around common research programs. It may be noted the European alliance SolLab and the network of international cooperation SolarPACES.

Among the research centers of international renowned include:

- the DLR (Germany)

- the NREL (The National Renewable Energy Laboratory - United States)

- the CIEMAT (El Centro de Investigaciones Energéticas Medioambientales y Tecnológicas - Spain)

- the CISRO (The Commonwealth Scientific and Industrial Research Organisation - Australia)

- the WIS (The Weizmann Institute of Science - Israel)

Baseline studies

End of 2011, there were already 234.6 GWth solar thermal installed around the globe, nearly 5 times more than photovoltaics at the same time! The majority of the power installed in China with nearly 152.2 GWth[11].

The global fleet of thermal sensors is made for 62.3% of vacuum tube collectors, 27.9% of flate plate collectors, 9.2% of unglazed collectors and only 0.7% of air collectors.

The global market is growing steadily every year especially through the facilities of vacuum tube collectors in China. They alone represent 65% of the installed capacity in 2011. This Chinese craze explains the strong growth of global solar thermal park since he was six-fold between 2000 and 2011.

Companies

Manufacturers

Vacuum tube collectors

| Companies | Countries | Annual production in 2012 in m² |

|---|---|---|

| Sunrain | China | 5 500 000 m² |

| Himin | China | 2 550 000 m² |

| Linuo Paradigma | China | 1 086 125 m² |

| TP Solar | China | 1 000 000 m² |

| Sunshore | China | 850 000 m² |

| Jixiang | China | 500 000 m² |

| Tsinghua | China | 300 000 m² |

| WesTech | China | 200 000 m² |

| Sunpower | China | 127 500 m² |

| High-New Technology | China | 110 000 m² |

Other manufacturers of vacuum tube collectors (by region):

| Regions | Countries | Companies |

|---|---|---|

| Europe | Germany | Akotec, Carl Capito, Consolar, Eurosun, Orange Energy, Ritter, RSF Solar, Soltark, Solvis, Westech Solar |

| Austria | Greenonetec | |

| Belgium | European Sopro | |

| France | Viessmann | |

| Greece | Calpak-Cicero, Sigma | |

| Hungary | Spring Solar | |

| Ireland | Kingspan Renewables | |

| Italy | Riello Group, Sunerg Solar, Thermics, Turco Group, Weppidoo | |

| Macedonia | Camel Solar, Leov | |

| Poland | Hewalex, Makroterm, Solar-Tech, Sunex, Watt | |

| Czech Republic | Regulus, VacuSol, Vermos | |

| Romania | Panosol Power | |

| United-Kingdom | SolarUk | |

| Sweden | HelioCaminus | |

| Swiss | AMK-Solar | |

| Ukraine | Star Energy | |

| America | United States | Sunmaxx |

| Mexico | Frantor | |

| Asia | China | Apricus, Arise New Energy, Ariston, CIB, Dr. Xia, Eurosun, Gaodele, Hejiasun, Shentai, Shune Aulun, Sunda, Viessmann, Wankang, XNE Group |

| South Korea | Solar Max | |

| India | Bipin Engineers, Energy, Greentek, Hykon Solar, Illusions4Real, Inter Solar, Kosol Hiramrut, NRG, Nuetech, Photon, Redren Energy, Savemax, Sudarshan, V-Guard | |

| Syria | Altawfeer | |

| Taïwan | Your Home | |

| Thaïland | Ravotek | |

| Turkey | Anadolu, Derya, Sergun |

Flat plate collectors

| Companies | Countries | Annual production in 2012 in m² |

|---|---|---|

| GREENoneTec | Austria | 595 000 m² |

| Five Star | China | 350 000 m² |

| Prosunpro | China | 340 000 m² |

| Soletrol | Brazil | 330 000 m² |

| Ezinç Metal | Turkey | 314 000 m² |

| Chromagen | Israel | 230 000 m² |

| Eraslandar | Turkey | 200 000 m² |

| Prime Laser Tech | Greece | 200 000 m² |

| Rheem | Australia | 260 000 m² |

| Wolf | Germany | 159 000 m² |

Other manufacturers of flat plate collectors (by region):

| Regions | Countries | Companies |

|---|---|---|

| Europe | Germany | Alpha-Innotec, Bosch Thermotechnik, Citrin Solar, emkaSol, ForSun, KBB, Nau, REM, Reinhard, Robin Sun, Rotex, Roth, Soleg, SolMetall, Solvis, STI, Thüsolar, Vaillant, Wagner, Wikora |

| England | AES, Discrete Heat, Sustainable Technologies, Viridian | |

| Austria | AKS Doma, Asgard, Cona, ESC Energy Systems, Gasokol, Siko Solar, SunWin, TiSun | |

| Belgium | European Sopro Energies | |

| Bulgaria | NES | |

| Cyprus | Metalco | |

| Croatia | Technomont | |

| Spain | Astersa, BDR Thermea, Cidersol, delpaso solar, Hucu Solar, OCV, Promasol, Soterna, Termicol | |

| Finland | Savo-Solar | |

| France | Vaillant, Clipsol, Viessmann | |

| Greece | Calpak Cicero, Cosmosolar, Dimas, Helioakmi-Megasun, Helional, Maltezos, Nobel Xilinakis, Papaemmanouel, Sigma, Sole | |

| Italy | Ariston, Cordivari, Costruzioni Solari, CMG, Riello, Sunerg | |

| Macedonia | Camel Solar, Leov | |

| Norway | Aventa, Catch Solar Energy | |

| Poland | ensol, Galmet, Geres Asco, Hewalex, Makroterm, Skorut, Sunex, Watt | |

| Portugal | Bosch Thermotechnik, Fogäosol, Openplus, Richworld Renewables, Solargus | |

| Czech Republic | Propuls, Solarex-Milan Slamina, Solarplus, Strojírny Bohdalice, Svoboda, T.W.I | |

| Russia | New Polus, Inten-1 | |

| Serbia | Elsol | |

| Slovenia | Lentherm-invest | |

| Sweden | Lesol, S-Solar | |

| Swiss | Ernst Schweizer, Soltop | |

| Ukraine | Sint Solar | |

| America | Argentina | Vetak, Innovar, Vademarco, Enersol, Cenit Solar, SOL |

| Brazil | A Atual, Aconobre, Bosch/Heliotek, Enalter, Jelly Fish, Solar Minas, Solis, Tuma | |

| Canada | Thermo Dynamics | |

| Chile | Britec, THC Solar | |

| United States | ACR Solar, AET, Integrated Solar, Magen eco-Energy, Solar Development, Solarhot, Solar Skies, SunEarth, Sunmaxx Solar, Sunsiaray | |

| Mexico | Captasol, Depsa, Grupo IUSA, Kioto Clean Energy, Módulo Solar, Oro Solar, Sunway de México | |

| Uruguay | Baroni Solar | |

| Africa | South Africa | Adzam Solar, Ikhwezi Solar, Powerz-on, Solardome, Solar Primeg |

| Kenya | Solimpeks | |

| Uganda | Solar Construct | |

| Tunisia | Sines | |

| Zimbabwe | Domestic Solar Heating | |

| Asia | China | Apricus, Arise, Bosch Thermotechnik, Dr. Xia, HaiLin, Innosolar, Jixiang, Sunda, Sunpower, Sunshore, Sunrain, TP Solar, Tsinghua, WesTech, XNE Group |

| South Korea | Jehin, Solar Max | |

| India | Ariston/Racold, Bhagyanagar, Bipin, Bosch Thermotechnik, Emmvee Solar Systems, Greentek, Inter Solar, Jain, Jay Renewable Energy, Kaushal, Kotal URJA, NRG, Nuetech Solar, Photon, Redren Energy, Savemax, Solchrome, Space Age, Sudarshan, TiSun, Tata Power, Vijaya Industries, | |

| Iran | Solarpolar | |

| Israel | Elsol, Magen eco-Energy | |

| Japan | Chiryu, Sunjunior | |

| Jordan | Hanania Solar Energy | |

| Turkey | Anadolu, Baymak/Baxi, Deyra, Erksolar, Sergün, Simsek Günes, Solarbooster, Solimpeks, Tansug Makina, Vaillant |

Installers

Links

| Magazines |

| Jobs |

| Research & Education |

| Organizations & Associations |

| Companies |

| Websites of particulars |

Notes and References

- Jump up ↑ The Olympic Museum, 2nd edition 2007 - The Olympic flame and torch relay :[1]

- Jump up ↑ F.S. Crofts & Co., New York 1937, An introduction to primitive culture : [2]

- Jump up ↑ E. Kreyszig, Archimedes and the invention of burning mirrors : an investigation of work by Buffon, in Geometry, analysis and mechanics, River Edge, NJ, 1994, p. 139-148

- Jump up ↑ Solar Cookers International Network, Horace de Saussure and his Hot Boxes of the 1700's: [3]

- Jump up ↑ Review of Mid- to High-Temperature Solar Selective Absorber Materials - C.E. Kennedy - NREL/TP-520-31267 (July 2002):[4]

- Jump up ↑ ACCIONA North America - Nevada Solar One:[5]

- Jump up ↑ Harvard - The Themis program and the 2500-kW Themis solar power station at Targasonne:[6]

- Jump up ↑ Aseanenergy.info - Detailed Performance Analysis of a 10 kW Dish/Stirling System:[7]

- Jump up ↑ Solar Tower - Solar Updraft Tower:[8]

- Jump up ↑ Areva - Kimberlina CLFRSolar Thermal Power Plant:[9]

- Jump up ↑ IEA SHC - Solar Heat Worldwide 2013:[10]

- Jump up ↑ Solrico - World Map of vacuum tube collector manufacturers 2013 :[11]

- Jump up ↑ Solrico - World map of flat plate collector manufacturers 2013:[12]