Difference between revisions of "Photovoltaic"

Solarpedia (Talk | contribs) (Created page with "Category:Photovoltaic Photovoltaic energy designates the transformation of light radiation into electricity. This energy from the Sun is a renewable energy. It was origina...") |

(No difference)

|

Revision as of 17:36, 20 April 2017

Photovoltaic energy designates the transformation of light radiation into electricity. This energy from the Sun is a renewable energy. It was originally used to power phones installed in remote areas, but it grew mainly thanks to the space industry. Photovoltaic energy has been widely democratized to finally raise on our rooftops and become an alternative energy for the future.

Contents

[hide]History

The history of solar energy begins in the 19th century, the century of the electric revolution. Alessandro Volta created the electric battery (1800)[1], in 1827 the Hungarian Ányos Jedlik made the first dynamo[2]. In 1879, Thomas Edison presented his first electric incandescent lamp[3] and built the first urban grid in direct current (1882)[4]. Seeing here a growing market, the industrial George Westinghouse with the help of the engineer Nikola Tesla, develops another grid in 1886, but this time in alternating current[5].

The electric revolution is also done by the discovery of photovoltaics. In 1839, Antoine César Becquerel (the grandfather Henri Becquerel), discovered the photovoltaic principle. The German physicist Heinrich Rudolf Hertz understood it and introduced the photovoltaic effect as such in 1887. But it was Albert Einstein who first, was able to explain the photovoltaic principle, and with the the added benefit, the Nobel Prize for Physics in 1921[6].

Despite the many advantages of this clean energy, the 20th century gives way to thermal energy from oil. Oil is plentiful, very cheap, it is considered as a strategic raw material, at the origin of the geopolitics of oil. Thus, solar is no more attractive, projects and discoveries become rare.

Photovoltaic technology grows in small steps. In 1954, U.S. researchers (Chapin, Fuller, Pearson and Prince) working for Bell Telephone Laboratories developed a photovoltaic cell with high yield of 6% in order to power the phones in remote areas. However the technology is still too expensive for widespread use[7].

Despite its cost, space research stimulate research in the field of photovoltaics. A cell with a yield of 9% is developed four years later and the first satellite with solar cells, Vanguard 1 is sent into space the 17th of March 1958[8].

We have to wait 1973 and the first oil shock that governments decide to change their energy sources. The research in alternative energies is accentuated. In the same year, the first house with a photovoltaic system is found at the University of Delaware in the United States.

In 1983, the Australian Hans Tholstrup travels 4000 km on "Quiet Achiever", the first solar car. He founded in 1987 the "World Solar Challenge", the first solar car race. Following the environmental awareness and rising fossil fuel of the twenty-first century, the policies for renewable energy have increased over the 5 continents.

Principle

Photovoltaic energy is obtained by means of a sensor called solar cell or photopile. These sensors are composed of semiconductor materials which have the characteristic to free electrons in an energy input. In the case of photovoltaics, photons (particles of light) provide the necessary energy to the electrons to break free and move in the matter, there is therefore creating of a electric current. This phenomenon is called the photoconductivity.

The semiconductor used for solar cells is mainly composed of Silicon, the same material used for integrated circuits. The main advantage is that it is available in almost unlimited quantities, since it is present in the sand in the form of silica and silicates. It is estimated that nearly 26% of the mass of the Earth's crust is made to silica[9].

All types of solar cells have a common architecture. It consists of a slice of semiconductor material sandwiched between two metal electrodes (+) and (-) for collecting the current generated by the release of electrons. These electrons flow from the electrode (-) to the electrode (+) by a potential difference between its terminals: the electrical dissymmetry. The potential difference is obtained by doping the front and rear parts of the wafer of semiconductor material:

- on the first face, a p-doped (positive) by the combination of boron atoms (B), containing fewer devices per electron than silicon atom;

- on the other side, an n-doped (negative), for the combination of phosphorus atoms (P) containing more devices per electron than silicon atom.

The different technologies

Photovoltaic energy is obtained using sensors called solar cells or photopiles. There are several solar cell technologies, but all are composed of semiconductor materials. The main semiconductor material used is silicon. Three technologies use this material:

- the amorphous silicon cell;

- the monocrystalline silicon cell;

- the multicrystalline silicon cell.

To a lesser extent, some cells are composed of another semiconductor such as cadmium telluride (Cd Te) or diselenide of copper and indium (CIS) material.

The amorphous silicon cell

The amorphous silicon cell is composed of a silicon having a disordered atomic structure, that is to say non-crystallized. This material absorbs light much more than crystalline silicon. It is belong to the technology "thin layer" which consist of vacuum deposition on a substrate (glass, metal, plastic, ...) a thin uniform layer composed of a more and more often powdered materials. The cells are dark gray.

Advantages:

- Can be applied over a large area (4 or 6 m2), and can then be cut;

- Can be used on curved or flexible modules;

- insensitive to heating at about 60 ° C;

- operates at a very low brightness level (from 20 lux);

- manufacturing in principle cheaper.

Disadvantages:

- performance much lower than that of crystalline silicon (<8% in trade);

- industrialization still underdeveloped compared to crystalline technologies;

- reduction in yield in the first weeks of exposure.

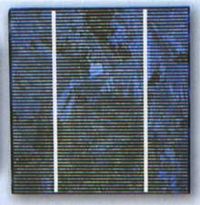

The monocrystalline silicon cell

The monocrystalline silicon cell is made of a silicon formed as one ordered crystal. This material is obtained directly from an germ or recrystallized at a high temperature as an ingot. It is then cut into thin wafers, which give the cells. These cells are generally uniformly blue.

Advantages:

- performance is very good (15-18%);

- Wp/m2 good ratio (~ 150 Wp/m2) which saves space if necessary;

- high number of manufacturers.

Disadvantages:

- manufacturing more difficult and therefore more expensive;

- poor performance in low light (operating range: 100 to 1000 W/m2);

- sensitive to heat, sharp decline of performance in around 60°C.

The multicrystalline silicon cell

The multicrystalline silicon cell (or polycrystalline) is composed of crystals of approximately 1mm to 2cm assembled called "grains". The plurality of crystals is formed during cooling of the silicon in the mold. The photovoltaic cell is bluish, but not uniformly, there are patterns created by different crystals.

Advantages:

- the cells may be square (with rounded corners for monocrystalline) for a better expansion in a module;

- good conversion efficiency (12-14%);

- ingot cheaper to produce than monocrystalline.

- high number of manufacturers.

Disadvantages:

- poor performance in low light (operating range: 200 to 1000 W/m2);

- sensitive to heat, sharp decline of performance in around 60°C.

Other technologies

The cells are also made with other materials such as gallium arsenide (GaAs), cadmium telluride (Cd Te) or diselenide of copper and indium (CIS) which has the advantage of strongly absorbing light, but handling is difficult and some materials such as cadmium poses problems of toxicity.

Gallium arsenide

This material has a very high yield, but is very expensive because of the elements used. It is used in space or on concentration systems.

Advantages:

- high efficiency (20-25%)

Disadvantages:

- high price

Cadmium telluride

This material absorbs light very well and can be deposited in thin layers. However its performance is still quite low and the toxicity of cadmium is a problem once the cell at the end of life.

Advantages:

- inexpensive ($ 0.98/W)

- good performance in low light conditions

- less sensitive to heat than silicon

Disadvantages:

- cadmium toxicity

Copper indium diselenide

This material is deposited on the thin layer cell by chemical methods or by a vacuum deposition of a layer of cadmium sulphide (Cd S). However, the toxicity of cadmium is a problem once the cell at the end of life.

Advantages:

- good resistance over time

Disadvantages:

- cadmium toxicity

- limited resources of indium on the earth

Applications

Photovoltaic power plants

Nowadays electricity is mass produced by thermal or nuclear power plants. For the sustainable development, it is interesting to consider a photovoltaic system in the tropics. Especially for the islands and other highly dependent region of oil or other fossil fuels for its electricity supply. However, such systems require a depreciation in the long term (beyond 15 years), but helps put in place by European states to subsidize facilities and the purchase price of "green" electricity allow a PV system connected to the network to be recovered in less than 10 years and enable research and industry to develop cheaper solar modules and better performance.

A solar photovoltaic power plant consists of a set of photovoltaic solar modules connected in series or in parallel and connected to one or more inverter (s). Solar power plants have a large power and are installed on dedicated areas, as opposed to the autonomous photovoltaic systems (power isolated homes, shelters ..) or decentralized solar systems connected to the network (installed on buildings of power generally lower 1MWc). This system produces electricity that is sent over the network.

The solar power plants have the advantage of being built anywhere as long as there was a power grid nearby. So they can be built on non-living areas, such as deserts, and have, for example, suntrackers devices to follow the course of the sun. Such devices also facilitate the combination of concentration systems, so optimizing the use of solar panels for example based on gallium arsenide. Power plants generally ranges from 1MWp to several tens of MWp.

The following list shows the largest photovoltaic plants in the world. The complete list of solar photovoltaic is updated regularly on the website pvresources.com.

| Power (MW peak) | Location | Description | Production (MWh/yr) |

|---|---|---|---|

| 250 MW | Agua Caliente Solar Project, United States | 5 200 000 modules First Solar on 960 hectares | 626 GWh, commissioning since December 2011 |

| 214 MW | Charanka, India | 2000 hectares | commissioning since December 2010 |

| 200 MW | Golmud, China | 564 hectares | 317 GWh, commissioning since October 2011 |

Today, photovoltaic solar power plants are hundreds, despite this ongoing projects are increasing.

Far from the central a few tens of MW, the U.S. leader First Solar, which specializes in technology-based panels cadmium telluride (CoC) plans to build two plants with a total capacity of 550 MW[10]. California energy company Southern California Edison will be responsible for its operation. The first called Desert Sunlight will be built from 2012 near Deser Center (Riversy County) and will have a capacity of 250 MW. The second called Stateline a 300MW power will be built the following year to the north of San Bernardino County. Both plants will be completed by 2015.

Even more ambitious project of solar electric generating power 2000 MW, representing an investment of $ 9 billion, was introduced in November 2009 by King Mohammed VI. The project is divided into five sites, which should be operational in 2020: Ouarzazate, Laayoune, Boujdour, Tarfaya and Ain Beni Mahtar. Each site will accommodate a power ranging from 100 to 500 MW. All represent an area of 10,000 hectares and an installed capacity of 2000 MW. For comparison, the power of an EPR reactor is estimated at approximately 1,500 MW.

In the same order, and at the same time (November 2009), First Solar has signed at the Presidential Summit China-US cooperation agreement with the Chinese government for the construction of a central 2 gigawatts (GW) to the Ordos City, Inner Mongolia[11]. The plant would be built in phases starting with the 30MW of the Phase 1. Phases 2, 3 and 4 are to be respectively 100MW, 870MW and 1,000 MW. Phases 2 and 3 should be completed in 2014 and Phase 4 in 2019.

Portable devices

The advantage of solar energy is the fact that generate electricity anywhere on earth as long as there is sunlight. She became one of the most convenient sources of energy to transport. Solar portable devices should work even if there is no sun. Most of the time, solar cells do not provide power directly to the device, but charge batteries that power the unit thereafter.

Thus a mobile device generally comprises:

- one or more cells

- a system for controlling charge / discharge (according to the quality of the product)

- a battery

The technologies used for solar cells are generally those in "thin" (amorphous silicon, cadmium telluride, ...) since it must resist any manipulation, unlike silicon-based cells that are very brittle. Among mobile devices, we have those where the cells are directly integrated into the system and others which become solar devices by adding a charger with solar cells.

Among these solar portable devices, we find:

- Solar Calculator;

- solar watch;

- solar radio;

- laptop solar (Sol);

- solar toys and gadgets;

- solar chargers.

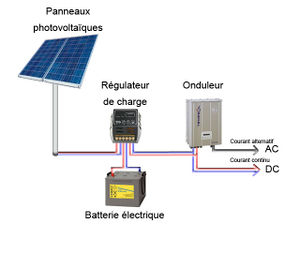

Structures or remote habitats

Some structures where habitats are difficult to access and therefore expensive to connect to the grid, and it is the case in the mountains or islands. In these cases, it is better to opt for a solar autonomous system called Stand-Alone System.

The use of an autonomous solar installation is to use the electricity produced directly or by storing it in batteries.

This installation consists of the following:

- one or more photovoltaic panel(s);

- a solar regulator;

- one or more storage batteries;

- an inverter (only for alternating current).

The main advantage of this system is that it is in some cases less expensive than electrical connection from grid, but photovoltaic electricity also helps to have a reliable source of energy without maintenance. Several structures have benefited from this system:

- the communications relay;

- sea and air traffic signals, railway;

- Emergency telephone;

- small meteorological stations;

- the safety of remote areas;

- pumping stations (developing countries, agriculture ...);

- systems for water purification;

- urban facilities (lighting, parking meters ...).

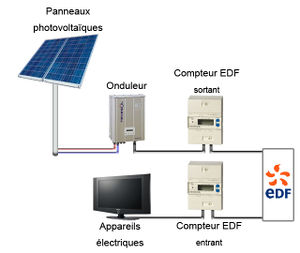

Structures or habitats connected to the grid

Where possible, photovoltaic panels can be connected to the grid. This system can produce energy that will be fully recovered as the network behaves like an unlimited storage.

The use of solar system connected to the grid involves the use of two electric meters, one for the outgoing energy (produced by solar panels), another for energy input (the network). The current product is not consumed directly but is usually fully injected into the network through an inverter.

This installation consists of the following:

- one or more photovoltaic panel(s);

- an inverter;

- an electric meter for outgoing energy;

- an electric meter for incoming energy.

The spatial domain

The spatial domain can be the main actor in the development of photovoltaic technology as we know it today. When the first photovoltaic cells were created, nobody wanted because they were too expensive. But space has seen in these cells to a suitable power satellites and contributed to the research and the emergence of the technology solution.

Outside the atmosphere, the solar radiation is an average of 45% greater than the surface of the Earth. It corresponds to that of the solar constant is about 1367 W/m2. In reality, the power varies continuously due to the slight eccentricity of Earth's orbit[12].

The first satellite sent into space with solar panels is Vanguard 1. It was launched into orbit on March 17, 1958. Vanguard 1 is composed of six photovoltaic cells which will power a transmitter 5 mW. The satellite stopped broadcasting in May 1964 and is currently followed by NORAD radar[13] or, occasionally, by optical means from the Earth.

Nowadays, satellite power was greatly increased to reach power from the kilowatt to ten kilowatts depending on their mission. Communications satellites needing more energy than satellite telescope type that come with passive instruments.

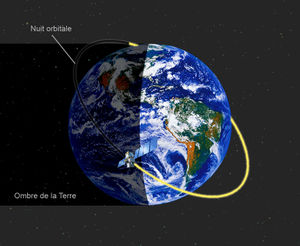

However, solar panels do not provide unlimited lives to their satellite. Satellites in low orbit (250km 2000km) pass into the shadow of the earth nearly 5,000 times per year, which wears very quickly batteries necessary for continuous operation of the satellite. This limits the lifetime of this type of satellite in about 5 years.

We find the same phenomenon for geostationary satellites which are located in them in high orbit (36 000 km). However, they pass through the shadow of the Earth only twice a year at the equinoxes. Cycles of charging and discharging of the batteries are negligible and will not reduce the extension of the life which is typically 10 to 15 years.

Research

Photovoltaic technology is still in its infancy and environmental policies promote research in this area. Research efforts are generally concentrated to reduce cost of electricity. The first way is to use alternative materials to silicon, the second way is the design of new methods of manufacture. A last line of research tends to reduce system costs by improving inverters, energy storage and the development of products for the building integration.

The materials of the future

The use of silicon quickly reached its limits in terms of performance. Despite this, manufacturing companies periodically announce higher yields through the use of new materials or concept; overview:

| Technology | Materials used | Principle | Efficiency |

|---|---|---|---|

| The polymer cells organic and inorganic | Polythiophene, Fullerene, polyfluorene,... | Polymer cells involve different molecular orbitals, some acting valence band, other conduction band between two distinct molecular species, one serving as an electron donor and the other acceptor. | 6% |

| The Grätzel cells | Tin oxide doped with fluorine SnO2•F, titanium oxide TiO2 impregnated ruthenium polypyridine, electrolyte iodide/triiodide (I–/I3–) | It is a photoelectrochemical system inspired from the organic photosynthesis made of a electrolyte as an electron donor (similar to the water in the photosynthesis) under the effect of an pigment excited by solar radiation (similar to the chlorophyll) | 11% in laboratory, 3% à 5% in commercial use |

| The transparent cells | Tin oxide with indium, phosphorus, zinc oxide, nitrogen[14] | The transparent cells operate in the same manner as the silicon cell with the difference that the donor and electron acceptor layers are formed using transparent materials. | Unknown |

The new processes

- CGIS cells is produced industrially and continuous by "Nanosolar" via a printing technique. Efficiecy 16% commercially, 20% in laboratory[15].

- Another alternative to the sawing developed by "Evergreen Solar" is the String-Ribbon process. It consists of passing a long wire in the molten silicon so as to obtain a long ribbon of silicon.

Improved systems

- Improving the energy efficiency for photovoltaic inverters. The current record is held by researchers at the Fraunhofer Institute for Solar Energy Systems ISE in reaching a efficiency of 99%.

- Integration of micro-inverter to the photovoltaic module.

Baseline studies

The total PV capacity installed the end of 2012 on the planet has reached 100 GWp, it allows the annual production of 110 TWh of electricity[16]. This may seem impressive, but it's all relative compared to the total electrical power installed and annual electricity production, all energy sources confounded : respectively a power of 5,067 GW (en 2010)[17] and an electricity production of 21,431 TWh[18].

Europe has the largest photovoltaic park with 70%, far ahead of China (8.1%), the United States (7.6%) and Japan (6.8%)[19].

The global market increase by steps. The annual capacity installed in 2008 and 2009 was approximately 7000 MWp, in 2011 and 2012 it was around 30 GWp, an annual market growing with an average of 44% since 2008!

As in France, technologies based on crystalline silicon dominate the world market with about 80% of production against 15% for thin film technology. The remaining 5% are shared by high-performance technologies and photovoltaic concentration.

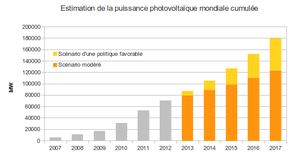

The PV capacity Installed on our planet is constantly growing and is evolving even exponentially. The annual global market is estimated at between 288 GWp and 423 GWp in 2017, an annual increase of 22% to 30%.

Companies

The producers of silicon

This is not the silica missing! Nearly 26% of the mass of the Earth's crust is composed. This raw material is used to obtain the silicon required for the manufacture of most of the photovoltaic panels. The producers of silicon transform silica ingots and platelet (wafers) after a process not always green... In 2013, between 260,000 and 370,000 tonnes [20] of solar grade silicon are removed from production plants.

| Companies | Countries | Annual capacity | Annual production in 2012 |

|---|---|---|---|

| GCL-Poly | China | 65 000 tonnes[21] | 37 055 tons |

| Wacker Chemie AG | Germany | 52 000 tons[22] | 38 000 tons |

| Origin of Chemical Innovation (OCI) | South Korea | 42 000 tons [23] | ? |

| Hemlock Semiconductor Corp. | United-States | 27 500 tons [24] | ? |

| Renewable Energy Corporation (REC) | Norway | 22 400 tons [25] | 21 702 tons |

| LDK Solar Co. | China | 17 000 tons [26] | 2 520 tons |

| Kumgang Korea Chemical Company (KCC) | South Korea | 12 100 tons[27] | 5 400 tons |

| SunEdison | United States | 10 000 tons[28] | 12 000 tons |

| Tokuyama Co. | Japan | 9 200 tons[29] | 7 800 tons |

| Timminco | Canada | ? | 1045 tons[30] |

| Daqo New Energy Co. | China | 7 300 tons[31] | 3 585 tons |

| M.Setek Co. | Japan | 7 000 tons[32] | 5 600 tons |

Other producers of silicon photovoltaic (by region):

| Continents | Countries | Companies |

|---|---|---|

| Europe | Germany | Joint Solar Silicon GmbH, Deutsche Solar AG |

| England | PowerFilm Inc., ICP Solar Technologies UK Ltd. | |

| France | Technip | |

| Russia | Nitol Solar, UC Rusal | |

| Slovenia | Metallurgija | |

| America | United-States | MEMC Electronic Materials |

| Asia | China | Asia Silicon Co., Aixin Silicon Sci-Tech Industrial Park, CSG Holding, Jaco Solarisi, Jiaozou Coal Industry Group, Jinyi Silicon, Luoyang Zhonggui, Na’Nan Sanjing Silicon, Ningxia Solar, NK Technology, Ningxia Sunshine Silicon Industry Company Ltd, Shangxin Silicon |

| Japan | JFE Steel, M. Setek, Mitsubishi Materials Corporation, Shin-Etsu Handotai, Sumco Corporation, Sumitomo Titanium Corporation, Tokuyama |

Manufacturers

To date, there are over 350 manufacturers photovoltaic cells and modules. However, the market is largely imposed by Asian companies. Only First Solar LLC and Canadian Solar Inc., respectively the American and Canadian companies stand out. In 2012, the 10 largest manufacturers of photovoltaic cells and modules share more than a third of the world market (14,495 MW produced for 38,500 MW installed)

| Companies | Countries | Technologies | Power produced in 2012 (in MW) |

|---|---|---|---|

| Yingli Green Energy | China | Polycristalline | 1 950,0 |

| First Solar | United States | Thin layer | 1 875,0 |

| JingAo Solar Co. Ltd | China | Monocristalline, Polycristalline | 1 700,0 |

| Trina Solar Ltd | China | Monocristalline, Polycristalline | 1 600,0 |

| Hanwha Group | China | Monocristalline, Polycristalline, Thin layer | 1 400,0 |

| Suntech Power Co. Ltd | China | Monocristalline, Polycristalline | 1 350,0 |

| Motech Solar | Taïwan | Monocristalline, Polycristalline | 1 280,0 |

| Canadian Solar Inc. | Canada | Monocristalline, Polycristalline | 1 240,0 |

| Gintech Energy Corporation | Taïwan | Monocristalline, Polycristalline | 1 100,0 |

| JinkoSolar Holding Co., Ltd. | China | Monocristalline, Polycristalline | 1 000,0 |

Other manufacturers of photovoltaic panels (by region)

| Regions | Countries | Companies |

|---|---|---|

| Europe | Germany | Aleo Solar, Centrosolar, Conergy, Deutsche Solar, Ersol, Heckert Solar, Scheuten Solar, Schott, Schüco, Solar Fabrik, Solarwatt, SolarWorld, Solon, Sunset Solar, Sunways, Systaic. |

| England | BP Solar | |

| Belgium | Issol, Photovoltec | |

| Spain | Isofoton, Fire Energy, Siliken | |

| France | Photowatt, Solairedirect, Tenesol | |

| Norway | Renewable Energy Corporation (REC) | |

| Netherlands | Shell Solar, Solland | |

| Czech Republic | Solartec Sro | |

| Swiss | Solterra Fotovoltaico | |

| America | United States | Sunpower Corp., Evergreen Solar, General Electric, Solterra, Sunpower |

| Asia | China | CEEG, CP Solar, Gesolar, Nanjing PV-tech, Ningbo Solar, Shanghai Solar, Shenzhen Topray, Trina Solar, Upsolar |

| Japan | Sharp, Kyocera, Honda Soltec, Kaneka, KIS Co, Mitsubishi | |

| Taïwan | Delsolar, E-ton Dynamics |

Installers

Classification IMS Research about global actors photovoltaic systems, has highlighted a global photovoltaic market fragmented "while the top 30 manufacturers only represent a combined market share of 24%, the same share as overall 2011 »by Ash Sharma, Director of specialist studies photovoltaics at IMS Research.

For the first time, First Solar is the first solar installer in the world with more than 500 MWp of projects completed in 2012. The ranking thus highlights an upheaval in markets where U.S. companies are taking advantage of the growing demand in Asia and the Americas. Thus, SunEdison, another American company gets 2nd place in the standings with 390 MWp. Chinese installers are also a notable appearance in the rankings thanks to the large local market, often impenetrable to foreign companies. Still, European companies defend themselves well in the world market like the German companies BELECTRIC, Juwi, Enerparc and the French company EDF Energies Nouvelles.

Below are the top 10 ranking IMS Research devoted to photovoltaic global actors in 2012:

| Ranking | Countries | Companies |

|---|---|---|

| 1 | United States | First Solar |

| 2 | United States | SunEdison |

| 3 | Germany | BELECTRIC |

| 4 | China | China Power Investment Corporation |

| 5 | Germany | Juwi |

| 6 | Germany | Enerparc |

| 7 | France | EDF Energies Nouvelles |

| 8 | China | TBEA Sun Oasis |

| 9 | China | GD Solar |

| 10 | China | Jiangsu Zhenfa New Energy |

Links

| Magazines |

| Jobs |

| Research & Education |

| Organizations & Associations |

| Companies |

| Websites of particulars |

Notes and References

- Jump up ↑ A provincial electrician in eighteenth-century England - Abraham Bennet F.R.S:[1]

- Jump up ↑ Made in Hungary: Hungarian contributions to universal culture - Andrew L. Simon:[2]

- Jump up ↑ Electric light - Thomas A. Edison:[3]

- Jump up ↑ newspaperarchive.com - The New-York Times, Tuesday, September 5, 1882:[4]

- Jump up ↑ The Day They Turned The Falls On: The Invention Of The Universal Electrical Power System:[5]

- Jump up ↑ The Nobel Prize in Physics 1921:[6]

- Jump up ↑ April 25, 1954: Bell Labs Demonstrates the First Practical Silicon Solar Cell:[7]

- Jump up ↑ U.S. Department of Energy - Solar History Timeline: 1900s:[8]

- Jump up ↑ WebElements - Silicon, the essentials:[9]

- Jump up ↑ First Solar, Southern California Edison Sign Contracts for 550 MW of Photovoltaic Solar Electricity: [10]

- Jump up ↑ First Solar : First Solar and China Guangdong Nuclear to develop Ordos solar project: [11]

- Jump up ↑ Construction of a Composite Total Solar Irradiance (TSI) Time Series from 1978 to present: [12]

- Jump up ↑ Real time satellite tracking - Vanguard 1: [13]

- Jump up ↑ BE Allemagne 441 du 17/06/2009, Des cellules solaires transparentes: [14]

- Jump up ↑ Technology Review - Advanced Solar Panels Coming to Market: [15]

- Jump up ↑ EPIA - Global Market Outlook for Photovoltaics 2013-2017 :[16]

- Jump up ↑ IEA - International Energy Statistics: [17]

- Jump up ↑ IEA - Key World Energy Statistics 2012: [18]

- Jump up ↑ EPIA - Global Market Outlook for Photovoltaics 2013-2017 :[19]

- Jump up ↑ JRC - PV Status Report 2013: [20]

- Jump up ↑ GCL-Poly Annual Report 2012:[21]

- Jump up ↑ Wacker Chemie AG Annual Report 2012:[22]

- Jump up ↑ OCI annual report 2012:[23]

- Jump up ↑ Hemlock Semiconductor Group – Fast Facts:[24]

- Jump up ↑ REC Annual Report 2012:[25]

- Jump up ↑ LDK Solar Co. Annual Report 2012:[26]

- Jump up ↑ JRC - PV Status Report 2013:[27]

- Jump up ↑ JRC - PV Status Report 2013:[28]

- Jump up ↑ JRC - PV Status Report 2013:[29]

- Jump up ↑ Timminco annual report 2008:[30]

- Jump up ↑ JRC - PV Status Report 2013:[31]

- Jump up ↑ JRC - PV Status Report 2013:[32]

- Jump up ↑ JRC - PV Status Report 2013:[33]

- Jump up ↑ IMS Research – Press Release - First Solar Ranked Largest Photovoltaic EPC in 2012 as European Companies Falter, 27 mars 2013: [34]